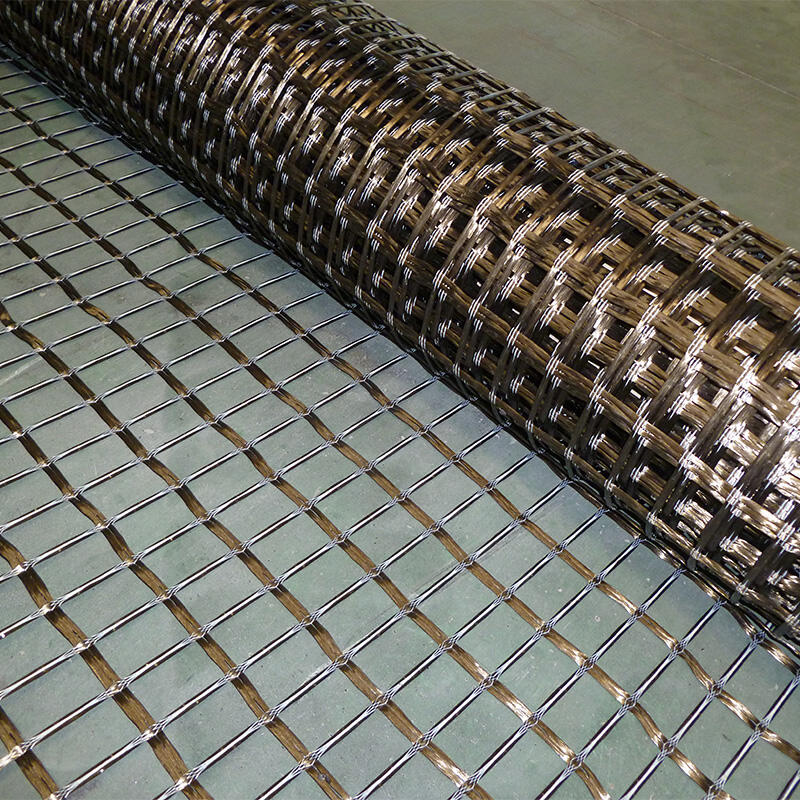

Mine Grid

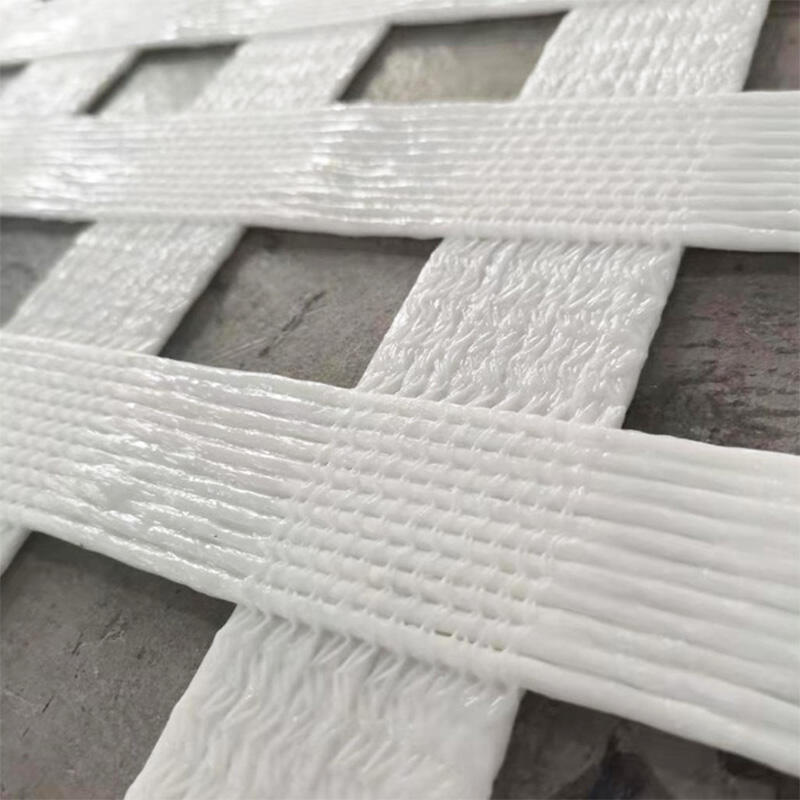

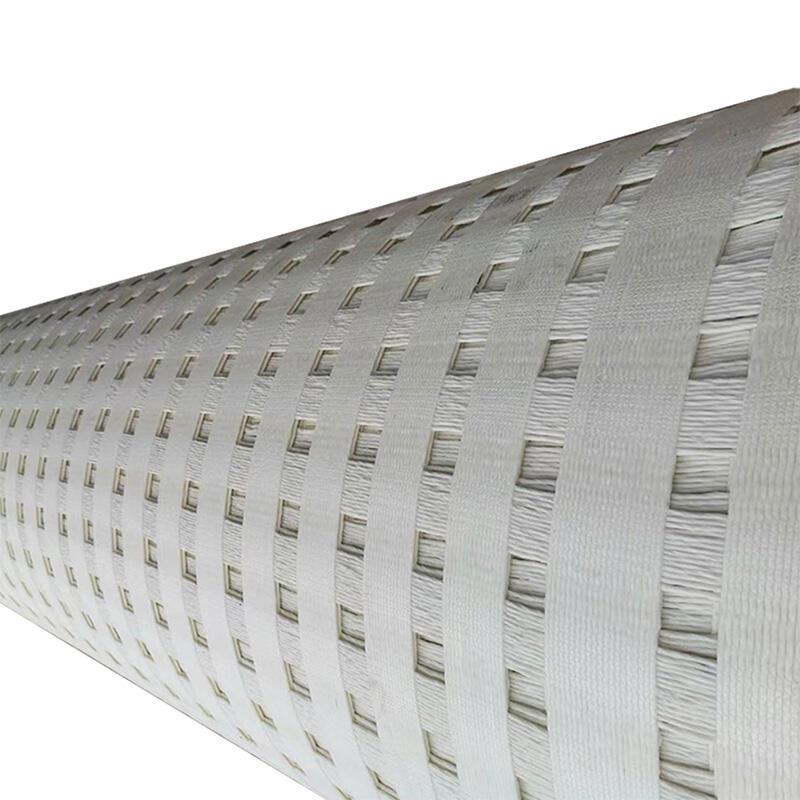

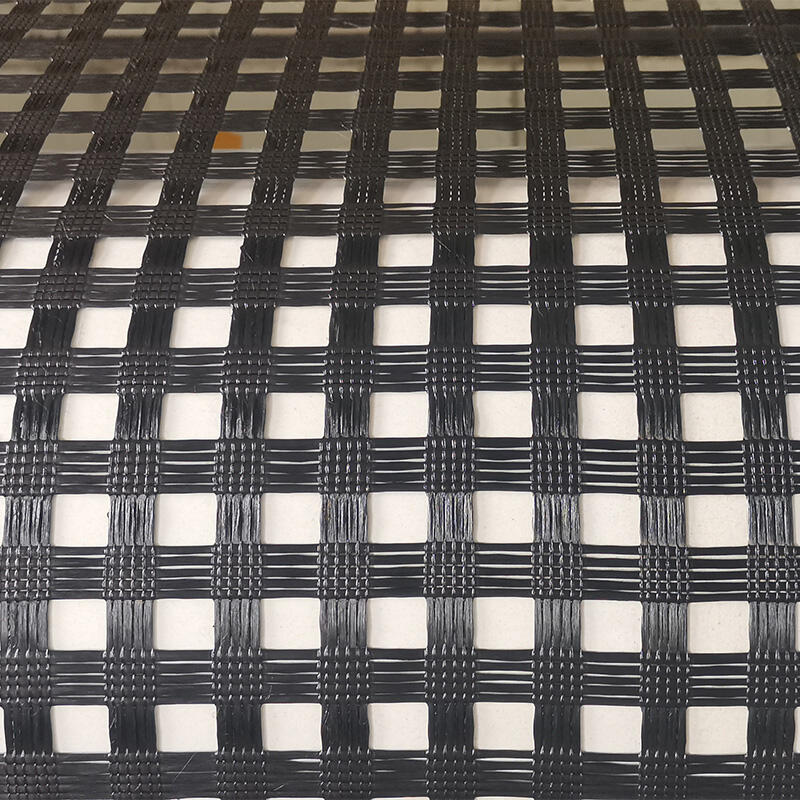

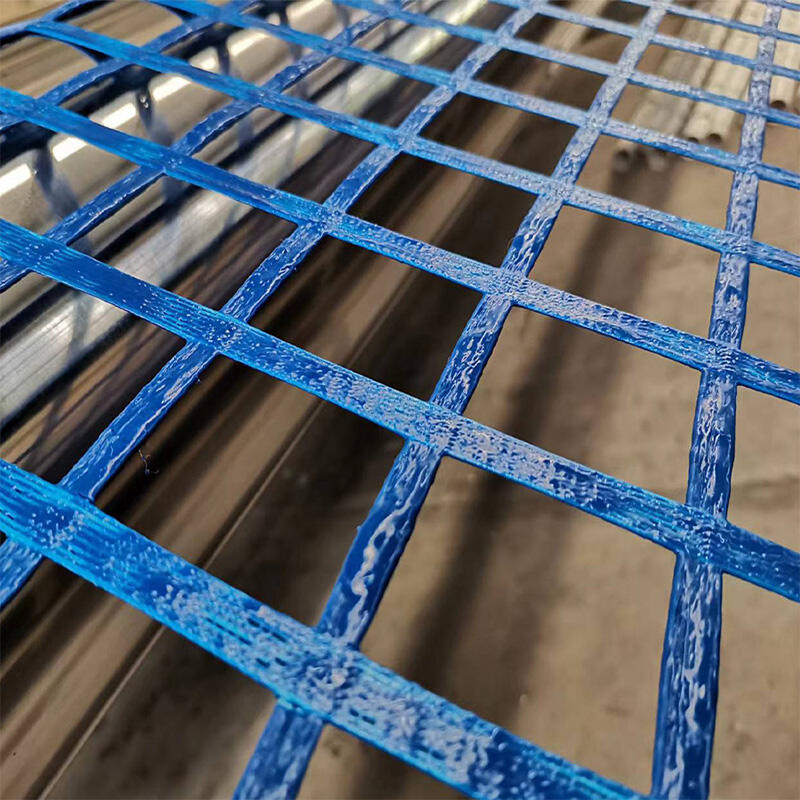

High reinforced Polyester Mine Grid is a kind of fake ceiling mesh mainly used for coal mine as well as other mines and underground civil engineering. It adopts high-modulus and high strength long polyester fiber warp knitted and bundled together as its body and then is coated with fire retarding and static conducting material. It is a good substitute for metal mesh, plastic mesh, steel-plastic composite mesh, packing belt mesh and etc.

- Overview

- Recommended Products

High reinforced Polyester Mine Grid is a kind of fake ceiling mesh mainly used for coal mine as well as other mines and underground civil engineering. It adopts high-modulus and high strength long polyester fiber warp knitted and bundled together as its body and then is coated with fire retarding and static conducting material. It is a good substitute for metal mesh, plastic mesh, steel-plastic composite mesh, packing belt mesh and etc.

Distinguished Characteristics

● Soft, light, high tensile and high strength of the junction.

● acid and alkali resistance, cold and moisture resistance.

● corrosion resistance, long life, fire retarding and and static conduction.

Parameters

| property/Specification | JD PET 40 | JD PET 50 | JD PET 60 | JD PET 70 |

JD PET 80 |

JD PET 100 | JD PET 120 | JD PET 160 | JD PET 200 | JD PET 240 | JD PET 300 | JD PET 300 | JD PET 400 | JD PET 600 | JD PET 600 | JD PET 700 | JD PET 800 | JD PET 1000 | JD PET 1200 | |

| Tensile strength (Kn/m) | Warp | 40 | 50 | 60 | 70 | 80 | 100 | 120 | 160 | 200 | 240 | 300 | 300 | 400 | 600 | 600 | 700 | 800 | 1000 | 1200 |

| Welt | 40 | 50 | 60 | 70 | 80 | 100 | 120 | 160 | 200 | 240 | 200 | 300 | 400 | 400 | 600 | 700 | 800 | 600 | 600 | |

| Breaking elongation(%) | <25% | |||||||||||||||||||

| Mesh Size(mm) | 25.4×25.4 50.8×50.8 76.2×76.2 | |||||||||||||||||||

| Aperture(mm) | 20×20 40×40 50×50 | |||||||||||||||||||

| Width(m) | 1-6m | |||||||||||||||||||

| Flame Vertardate(s) | Flame:<3 Non-flame:<10 | |||||||||||||||||||

| Static Conduction(Ω) | <1.0× 10⁹v | |||||||||||||||||||

Application

● Fake ceiling supporting in stoping face.

● Anchoring and shotcreting tunnel supporting.

● Temporary and permanent supporting in tunnel.

● Other mining tunnel projects and underground civil engineering.

Benefits

● Avoiding tunnel sliding, leakage of gangue and roof falling and improving mine safety and reducing mining accidents.

● Reducing ventilation resistance and saving energy.

● Recyclable and easy installing.